Robotic Collaborative System

VR-1000

Robot Cooperation Application

The VR-1000 Robotic Collaborative System is a relatively advanced transformation application in recent industrial automation machinery. It is used in the food production process to transform the original manual or semi-automatic process into less manual or even fully unmanned automatic production, which greatly improves production efficiency and solves the current labor shortage problem in the food baking industry.

The machine contains the following features:

1. Use high-pixel visual recognition system to accurately locate and pick up random products

2. The soft/hard jaws can be flexibly replaced according to the product properties

3. Integrate IoT technology to digitize and control process-related data.

The robotic-arms that have been widely used in industrial automation machinery also can be integrated into the food production process, replacing the traditional manual or semi-automated processes in the production process. For example, the “Balls Placing “at the intermediate or latter sections of the green onion pancake cake/Paratha production line, the “Gripping, Moving, Positioning, Dropping” at the packing section of pastry/mochi/snack production line. This will enable the food production line to complete production under less-artificial and more hygienic conditions, and it makes the fully unmanned automation in food production achievable.

Specification

- Power Supply: 220/380V, 3PH, 50/60Hz, 1.5KW

- Machine Dimension: L2,700 x W1,320 x H2,120 mm

- Machine Weight: 700 KG

- Rotation Diameter: 950 mm

Manufacture Product

- Food packaging process, Positioning, Clamping, Box Dropping, Unmanned Automated Food Packaging

Training and service

Our professional training and after sale service group will teach you how to use the machine in the short time and supply sufficient information afterward.

- Movies

- Photo Gallery

- Related Products

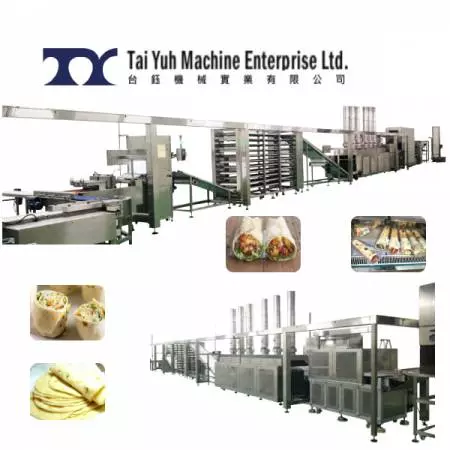

Chinese Flaky Scallion Pancake Production Line

TY-3168

To make machine-made spring onion pies close to manual-made one, we reform dough rolling and stretching...

DetailsAutomatic Puff Pastry Machine

TY-3000M

TY-3000M Puff pastry machine produce layered puff pastry sheets automatically with satellite...

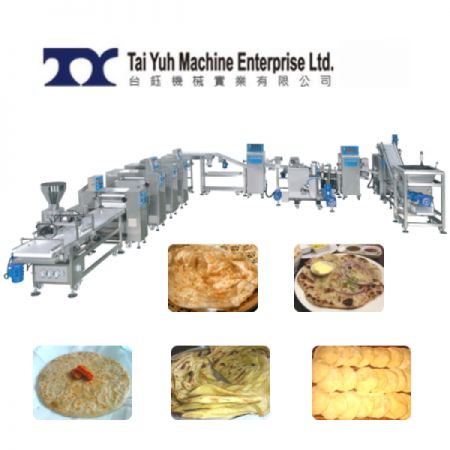

DetailsAutomatic paratha making machine

TY-3000L

TY-3000L Paratha making machine can make layer paratha automatically. With satellite rollers,...

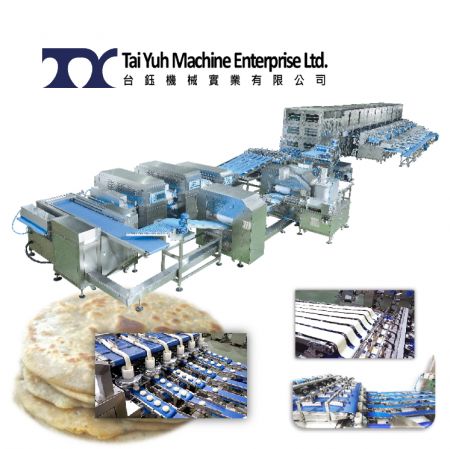

DetailsMexican Tortilla/Indian Chapati Making Line

Tortilla/Chapati Making Line

Mexican Tortilla is derived from Maya civilization in Latin American initially; it is made...

DetailsAutomatic Dough Dividing and Rounding Machine

DR-6

Automatic Dough Dividing and Rounding Machine divide the dough equally into small dough then...

DetailsParatha pressing Machine

TY-788

It would save much of your time using machine to press pancakes instead of hand make.Put dough...

Details

Robotic Collaborative System | Advanced Puff Pastry Machine for Professional Bakeries

Based in Taiwan and established in 1993, Tai Yuh Machine Enterprise Ltd. specializes in manufacturing high-quality food processing machinery. Their product range includes steamed bun machines, stuffed bread making machines, dumpling machines, puff pastry machines, and tortilla/chapati making lines. Renowned for their innovative design and efficiency, Tai Yuh's machines are ideal for commercial and industrial food production, catering to international markets with reliable and customized solutions.

Tai Yuh offers a comprehensive one-stop manufacturing service, providing end-to-end solutions from design to production. With a global reach, their machines have been sold to over 20 countries, establishing a strong international presence and reputation for excellence in food processing equipment.

Tai Yuh has been providing high-quality food stuffing and forming machines, alongside related equipment since 1993. With advanced technology and 30 years of experience, Tai Yuh ensures each customer's demands are met.