Automatic paratha making machine

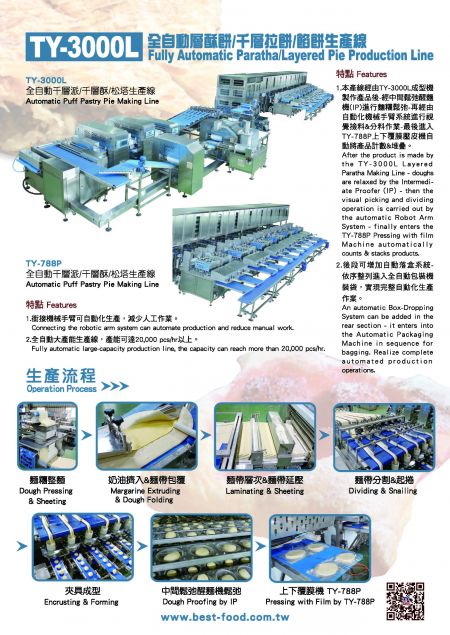

TY-3000L

Automatic roti maker

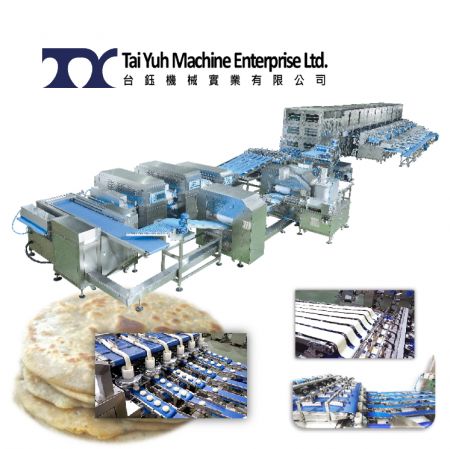

TY-3000L Paratha making machine can make layer paratha automatically. With satellite rollers, butter extruder and 1 set folding device.

The paratha sheet laminating line is with special design dough rolling and sheeting mechanisms which won't apply much energy to dough sheet that can keep taste similar to manual made.

TY-3000L Automatic paratha making machine can be set up in L-shape and I-shape depends on the given space available and the type of production.

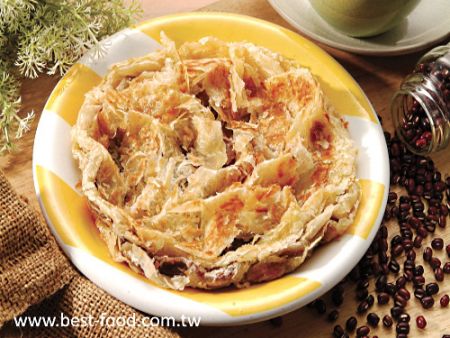

Pastry sheet with multilayers

TY-3000L pastry machine can make pastry sheets with 13 layers.

The layer paratha pastry is created by pressing together alternating layers of dough and butter,generally butter is spread on a thin layer of the dough, and then the dough is folded and rolled out repeatedly to create many alternating layers

Collocate with filling mechanism can make stuffed paratha or stuffed pastry bread.

Specification

3,000pcs/hr(base on 130g/pc)

3,500pcs/hr(base on 90g/pc)

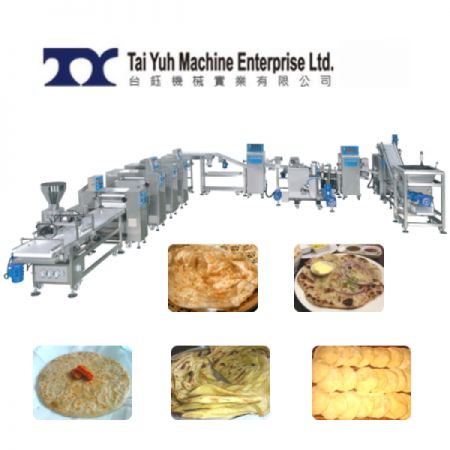

Manufacture Product

- Automatic paratha making machine can produce, bread, roti paratha, layered omelet, layered dough band, pastry dough band…etc.

Training and service

Our professional training and after sale service group will teach you how to use the machine in the short time and supply sufficient information afterward.

- Movies

- Photo Gallery

- Related Catalogue

- Related Products

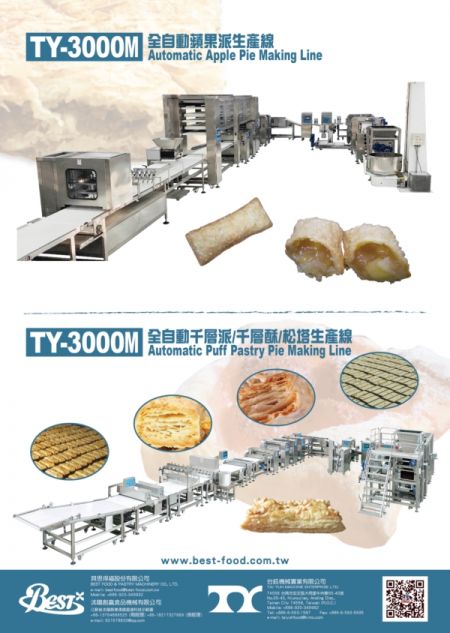

Automatic Puff Pastry Machine

TY-3000M

TY-3000M Puff pastry machine produce layered puff pastry sheets automatically with satellite...

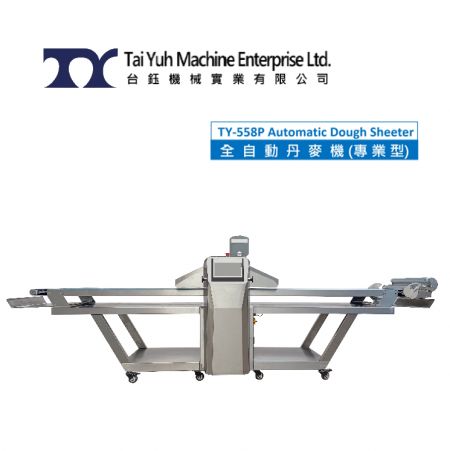

DetailsAutomatic Dough Sheeter

TY-558

TY-558 stores 10 single or compound programs. Up to 18 continuous operation steps can be designed...

DetailsHeating & Pressing Machine

TY-777

To heat and press various types of flour-made pancakes at the same time. TY-777 Heating and pressing...

DetailsParatha pressing Machine

TY-788

It would save much of your time using machine to press pancakes instead of hand make.Put dough...

Details

Automatic paratha making machine | Advanced Puff Pastry Machine for Professional Bakeries

Based in Taiwan and established in 1993, Tai Yuh Machine Enterprise Ltd. specializes in manufacturing high-quality food processing machinery. Their product range includes steamed bun machines, stuffed bread making machines, dumpling machines, puff pastry machines, and tortilla/chapati making lines. Renowned for their innovative design and efficiency, Tai Yuh's machines are ideal for commercial and industrial food production, catering to international markets with reliable and customized solutions.

Tai Yuh offers a comprehensive one-stop manufacturing service, providing end-to-end solutions from design to production. With a global reach, their machines have been sold to over 20 countries, establishing a strong international presence and reputation for excellence in food processing equipment.

Tai Yuh has been providing high-quality food stuffing and forming machines, alongside related equipment since 1993. With advanced technology and 30 years of experience, Tai Yuh ensures each customer's demands are met.